Proper Maintenance Saved a Gun Manufacturer over $200,000

Background

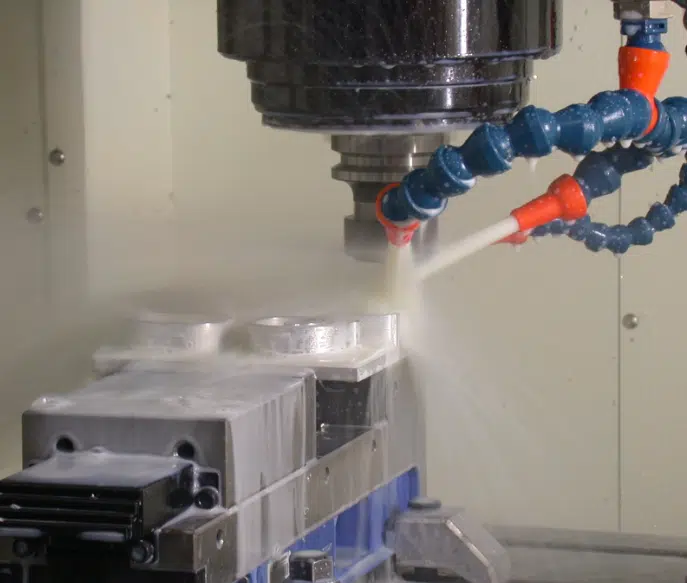

A gun manufacturer located in the Chicagoland area was facing a serious problem with their coolant smoke and mist air filtration system. They manufactured parts for guns that required a high level of precision. Their precision CNC machines caused an air quality problem because of the coolant sprayed on the cutting tools.

High-speed machining with high pressure coolant causes a significant amount of mist and smoke particles that need to be collected. All of their CNC machines had some type of air filtration system, but they did not seem to be doing the job, and filtering the contaminants from the air.

Problem

Their existing air quality system was not working as it should. The poor air quality was causing problems with employee morale, creating health and safety issues, and causing an HR nightmare. The company was facing the possibility of purchasing an additional ambient air filtration system to try and further improve the air quality. This would have cost the company around $200,000 to be installed, as well as additional maintenance costs.

Solution

To solve this problem, the gun manufacturer reached out to Bee Clean, a company that specializes in the maintenance of electrostatic air cleaners, as well as selling and installing new air filtration systems. They approached us about installing a new air filtration system, but we recommended that they first do a full service and repair anything that we found on their existing system before spending on a new system. They agreed to give this a try.

Their existing MistBuster equipment was adequate and efficient for the smoke and mist that they were producing, but it had not been serviced properly in many years. We identified and repaired the problems caused from a lack of maintenance on their MistBusters and recommended that the company schedule regular maintenance for their air filtration system.

The maintenance services included cleaning and replacing the air filters, checking and cleaning contacts, inspecting the high-voltage system, and ensuring the proper function of each MistBuster.

After a few months of proper maintenance on their air quality system, it became clear that it was doing a great job at removing the airborne contaminants created by their CNC machines. With the air quality significantly improved, they no longer needed the additional ambient air filtration system.

Result

After implementing Bee Clean’s recommended maintenance services, their coolant smoke and mist air filtration system began working properly again. The company resolved many of their HR issues and was able to keep up with the high demand for their products. They also avoided the costly expenses of purchasing an additional ambient air filtration system. This saved the company over $200,000 in unnecessary expenses.

This company was extremely satisfied with Bee Clean’s services and has continued to schedule regular maintenance for their coolant smoke and mist air filtration system to ensure it continues functioning correctly. This partnership has helped this Gun Manufacturer maintain their high production standards and continue providing their customers with high-quality products.

The regular maintenance services also helped extend the system’s life and prevented future breakdowns. This resulted in significant cost savings for the company in the long run.